Previous

Next

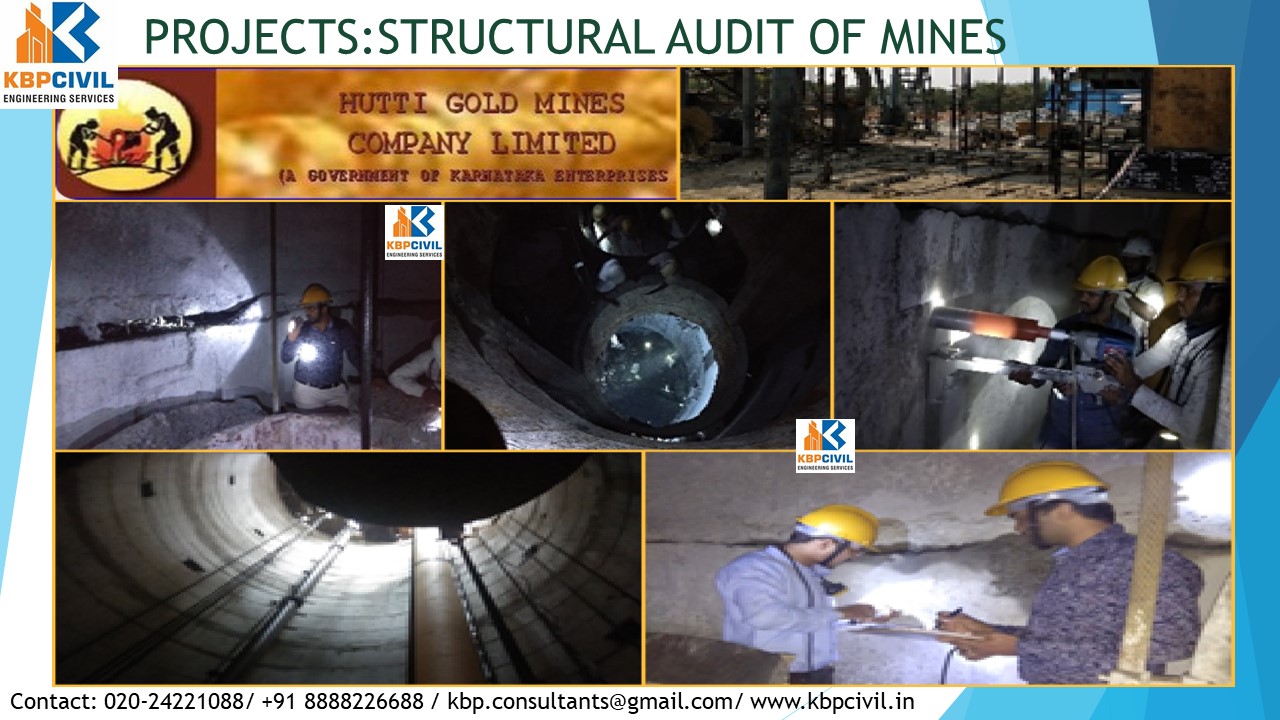

The durability of existing structures always depends upon the properties of hardened concrete, steel, brick, timber and their connections. To find the safety of any existing concrete structures, we need a set of tests to evaluate the safety parameters. Non-destructive tests are that kind of tests, which place a vital role in evaluation of existing structures regarding their strength and durability.

KBPCES brings an unparalleled capability in assisting clients in the process of understanding the condition of structures through our ability to combine our Engineering Expertise with Market leading suite of destructive and non-destructive field and laboratory tests. KBPCES provides a wide range of destructive and non-destructive tests to characterize critical structural properties. These include:

Ultrasonic Pulse Velocity Test:

To access Quality / Compressive Strength of Concrete, Presence of Cracks & Depth of Crack.

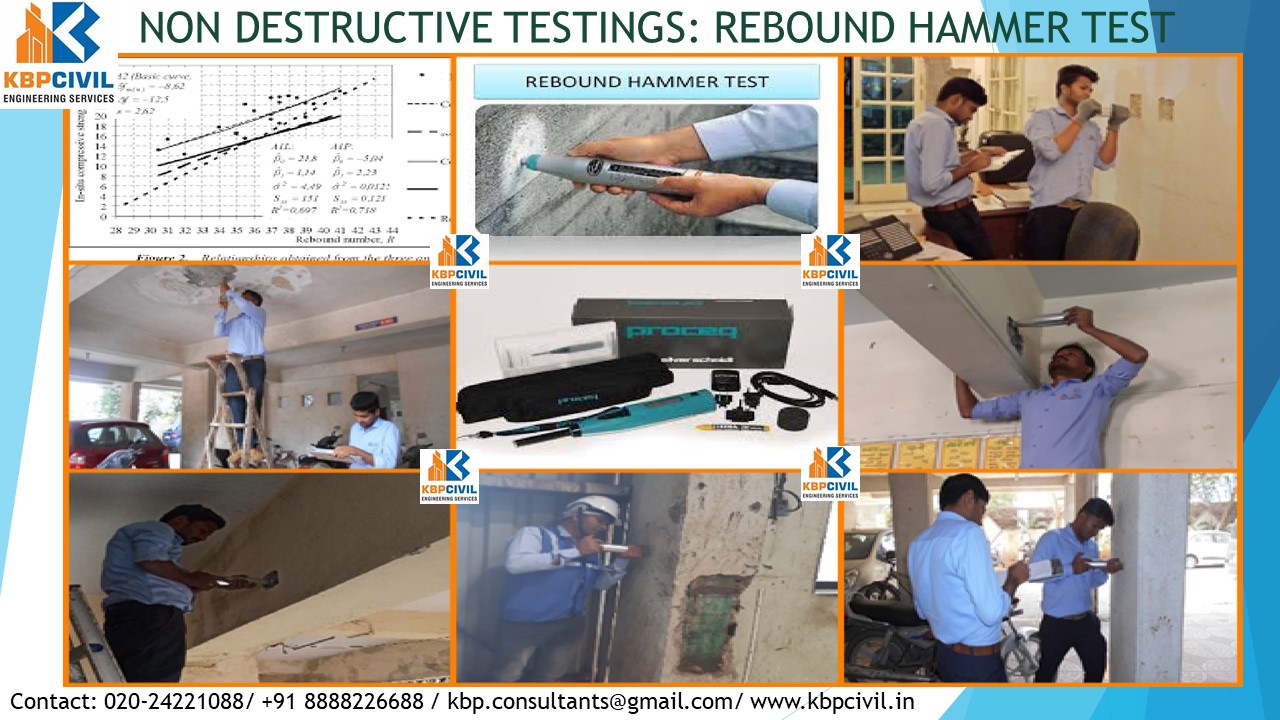

Rebound Hammer Test:

Convenient and Rapid Indication of Surface Compressive Strength Up To 50mm Depth of Concrete.

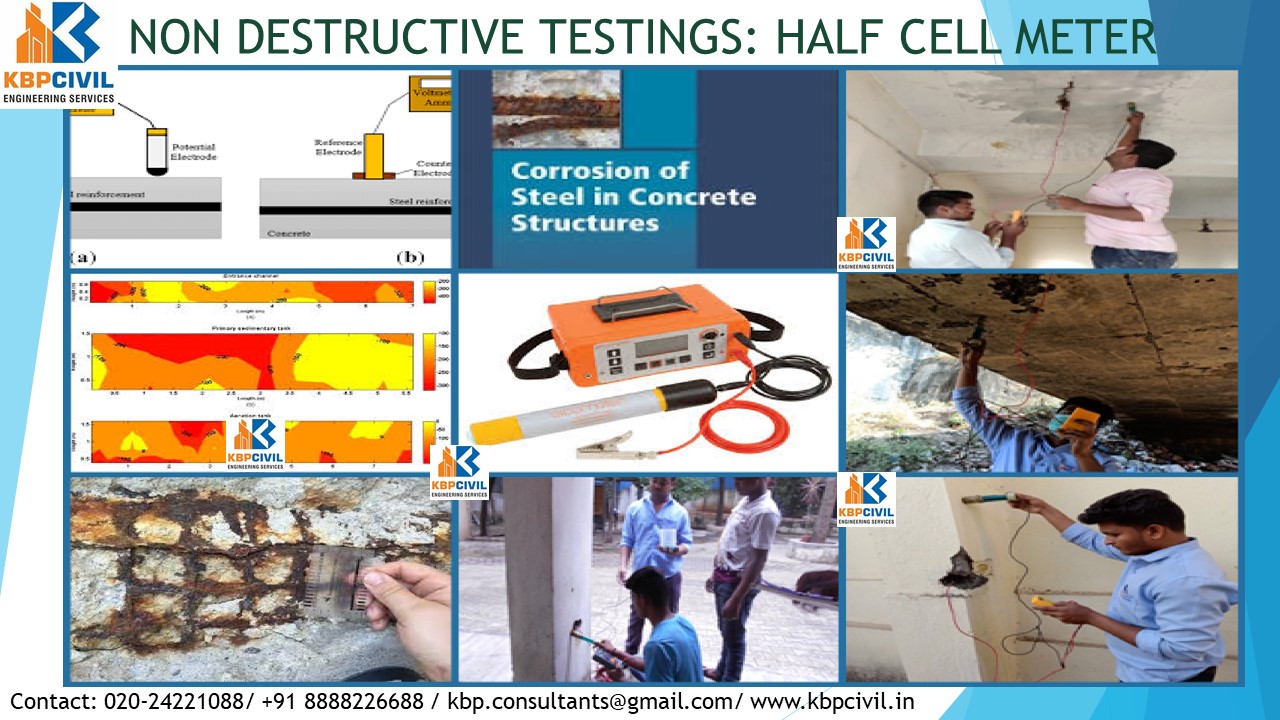

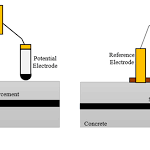

Half-Cell Potential Test:

Determination of Corrosion Activity / Percentage of Corrosion the Reinforcing Steel in RCC Members.

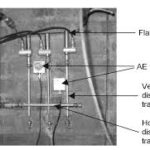

Flat Jack Test:

To Determine the Acting Stresses (Single Flat Jack) Or to Evaluate the Mechanical Parameters of The Masonry/Concrete Structures.

Vibration Test:

To measure Structural Displacement, Acceleration (Vibration) under the given loading condition.

Ultrasonic Thickness Gauge:

Rapid Non-Destructive Accurate Thickness Testing of Metal Structural Members.

Moisture Test:

To identify source of the leakages and dampness place by using moisture meter. This measure moisture percentage.

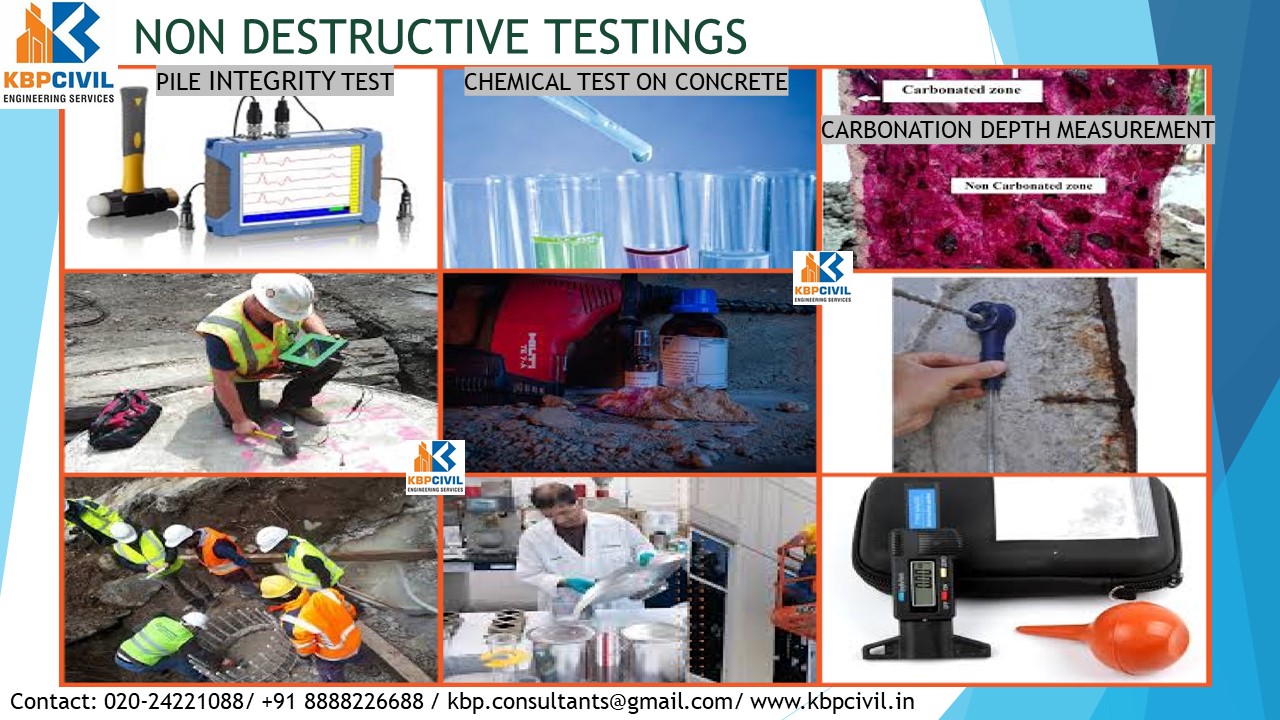

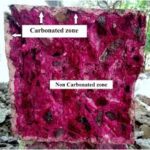

Carbonation Test

To Determining the Depth of The Carbonated Layer on The Surface of Hardened Concrete by Means of An Indicator called as phenolphthalein.

Chemical Test (Sulphate / Chloride Content/PH):

To determine percentage of chloride/ Sulphate content in concrete and testing PH Value of concrete.

Infrared Thermometer Test:

To Monitoring or control Temperatures in building structures Using IR Thermometers.

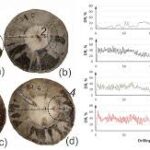

Concrete Core Compression Test:

To Extract Concrete Core and Test for The Determination of Compressive Strength and Quality of hardened Concrete in The Structure.

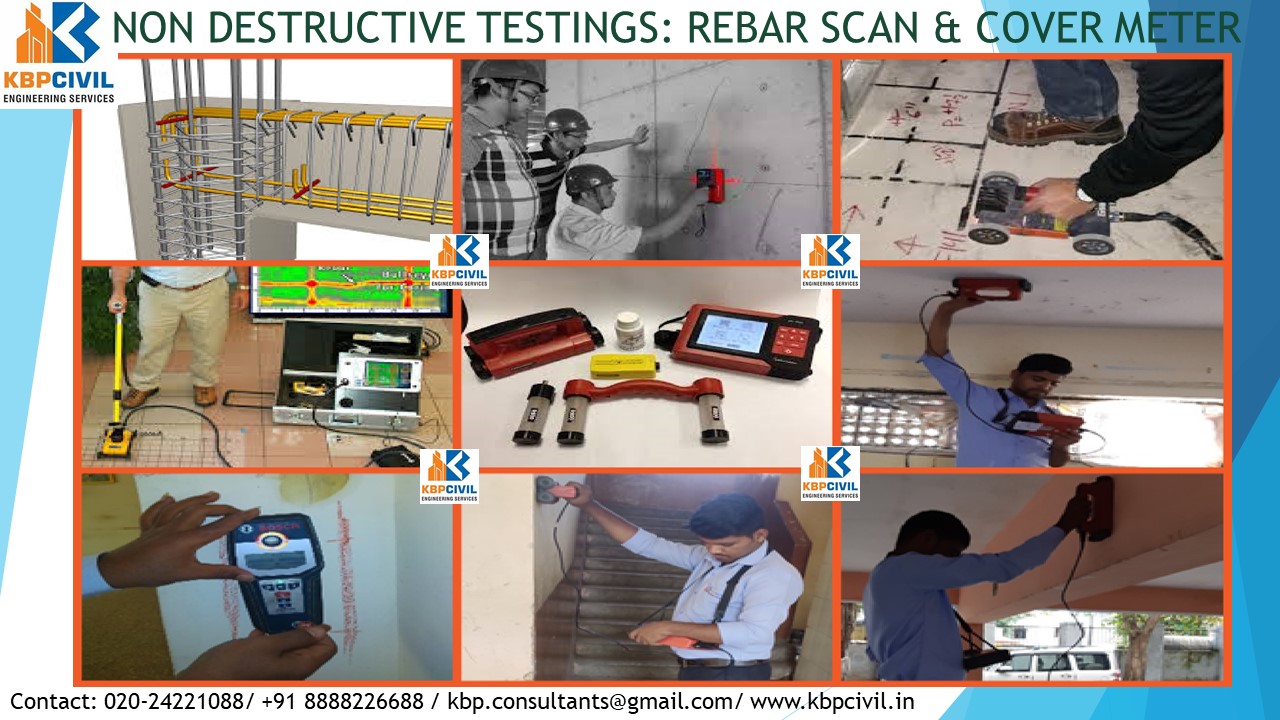

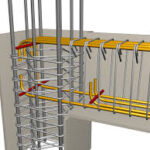

Rebar Location & Cover Meter Test:

Used to Specify the Location of Reinforcement Bars in Concrete and Determine the Exact Concrete Cover provided to reinforcement.

Pile Integrity Test:

To Measure Cross-Sectional Area, Length, Continuity and Consistency of The Pile. Integrity testing of Pile to discover any flaws before they can cause any damage.

Micro-Drill Test on Timber:

To Assess the condition of timber member and joints for identify voids, decay, insect damage, and cracks.

Drone Camera Inspection:

To inspect the inaccessible structures like Transmission Towers, Chimneys, Bridges, Tall structures, Multi storey buildings

Endoscopy / Bore scope Camera Inspection:

To access Quality / Compressive Strength of Concrete, Presence of Cracks & Depth of Crack.

Under Water Test:

To identify source of the leakages and dampness place by using underwater test. This measure moisture percentage.

Slab Load Test:

To evaluation of strength/ Capacity of concrete structures (flexural members & Bridges) by using physical load test method.

Ground Penetrating Radar Test:

To Locate defects in the underground structures, Locate underground objects, Utilities by using high frequency radio waves.

Magnetic Particle Inspection of welding:

For detecting surface discontinuities such as crack which are impossible to see with the naked eye.

Liquid Dye Penetrant Testing:

To detects surface cracks, leak detection by using dye penetrants specially for Members of non-magnetic materials such as aluminum.

Ultrasonic Inspection of Metal Members:

To detects both surface and sub-surface flaws in metal members which are not detected by other methods.

Industrial Radiography Inspection:

To detect microscopic internal flaws such as cracks, porosity, blowholes, non-metallic inclusions, incomplete root penetration and undercutting in Metal Structural Members by using x-ray.

Ultrasonic Pulse Velocity Test: To access Quality / Compressive Strength of Concrete, Presence of Cracks & Depth of Crack.

Rebound Hammer Test: Convenient and Rapid Indication of Surface Compressive Strength Up To 50mm Depth of Concrete.

Half-Cell Potential Test: Determination of Corrosion Activity / Percentage of Corrosion the Reinforcing Steel in RCC Members.

Flat Jack Test: To Determine the Acting Stresses (Single Flat Jack) Or to Evaluate the Mechanical Parameters of The Masonry/Concrete Structures.

Vibration Test: To measure Structural Displacement, Acceleration (Vibration) under the given loading condition.

Ultrasonic Thickness Gauge: Rapid Non-Destructive Accurate Thickness Testing of Metal Structural Members.

Moisture Test: To identify source of the leakages and dampness place by using moisture meter. This measure moisture percentage.

Carbonation Test: To Determining the Depth of The Carbonated Layer on The Surface of Hardened Concrete by Means of An Indicator called as phenolphthalein.

Chemical Test (Sulphate / Chloride Content/PH): To determine percentage of chloride/ Sulphate content in concrete and testing PH Value of concrete.

Infrared Thermometer Test: To Monitoring or control Temperatures in building structures Using IR Thermometers.

Concrete Core Compression Test: To Extract Concrete Core and Test for The Determination of Compressive Strength and Quality of hardened Concrete in The Structure.

Rebar Location & Cover Meter Test: Used to Specify the Location of Reinforcement Bars in Concrete and Determine the Exact Concrete Cover provided to reinforcement.

Pile Integrity Test: To Measure Cross-Sectional Area, Length, Continuity and Consistency of The Pile. Integrity testing of Pile to discover any flaws before they can cause any damage.

Micro-Drill Test on Timber: To Assess the condition of timber member and joints for identify voids, decay, insect damage, and cracks.

Drone Camera Inspection: To inspect the inaccessible structures like Transmission Towers, Chimneys, Bridges, Tall structures, Multi storey buildings

Endoscopy / Bore scope Camera Inspection: To inspect the in-accessible areas of structures, building components, Heritage structures, pipes etc.

Underwater Inspection: To inspect underwater structures such as Bridge piers, Pile foundations, Dam, underground Water tanks by remotely operated vehicles.

Slab Load Test: To evaluation of strength/ Capacity of concrete structures (flexural members & Bridges) by using physical load test method.

Ground Penetrating Radar Test: To Locate defects in the underground structures, Locate underground objects, Utilities by using high frequency radio waves.

Magnetic Particle Inspection of welding: For detecting surface discontinuities such as crack which are impossible to see with the naked eye.

Liquid Dye Penetrant Testing: To detects surface cracks, leak detection by using dye penetrants specially for Members of non-magnetic materials such as aluminum.

Ultrasonic Inspection of Metal Members: To detects both surface and sub-surface flaws in metal members which are not detected by other methods.

Industrial Radiography Inspection: To detect microscopic internal flaws such as cracks, porosity, blowholes, non-metallic inclusions, incomplete root penetration and undercutting in Metal Structural Members by using x-ray.